Liquid cryogenic storage and distribution vessels

GazSurf offers to supply cryogenic storage vessels of different volume for long-term storage of liquid cryogenic products.

The vessels are manufactured at the best partner vendors or at the company’s own production facilities.

Stationary pressurized cryogenic storage vessels

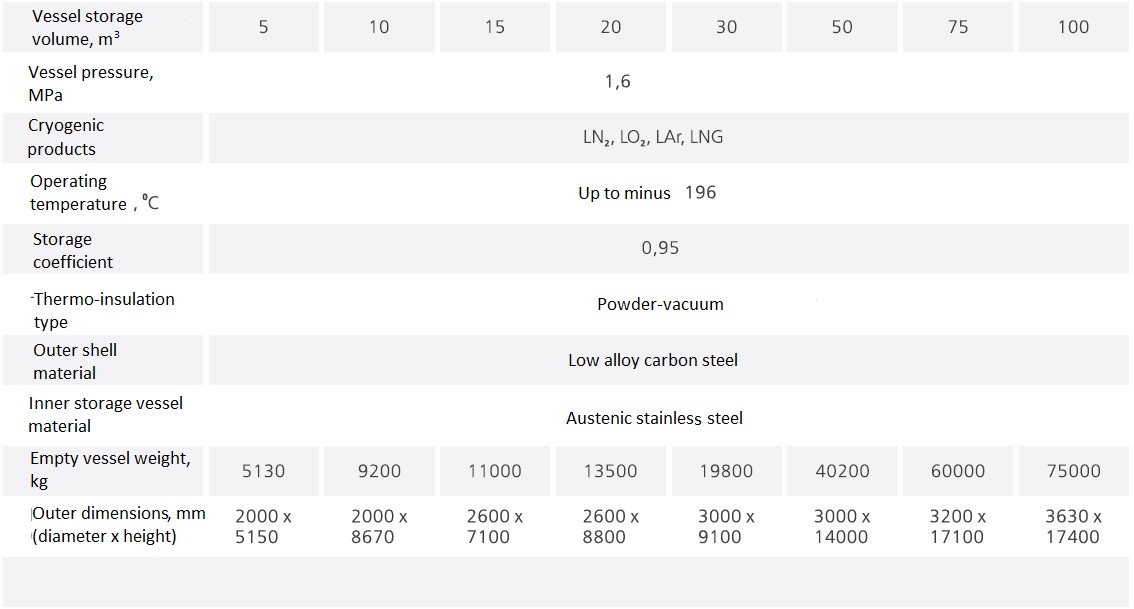

“GazSurf” offers to supply stationary cryogenic vessels varying in storage volume from 5 up to 100 m3 for storing and distributing liquid products such as nitrogen (LN2), oxygen (LO2), argon (LAr), liquefied natural gas (LNG).

From the construction standpoint a stationary cryogenic reservoir is comprised of two vessels — an inner storage tank inside an outer shell. The inner vessel is manufactured out of stainless steel, the outer (shell) is manufactured from carbon steel. To reduce heat transfer from the outer to the inner vessels (thus decreasing the rate of liquid product evaporation) the space in-between the walls is filled with a thermoinsulating material — perlite. The space then is additionally vacuumed to further reduce heat transfer.

Scope of supply of the stationary cryogenic storage reservoirs:

• pressurization evaporator (for keeping the pressure inside the storage tank on a set level);

• block, regulating and safety valves that is required for the process — both with manual and remotely operated actuators;

• measuring instruments (pressure and product level controllers) with signal channels to be connected to a remote control station;

• anchor bolts.

100% of the supplied equipment passes rigorous factory safety tests at the vendor facilities before shipment. There is an opportunity to test the equipment additionally in accordance with norms and regulations of the sites where it will be operated or have the Customer present to witness the tests if required.

Stationary cryogenic storage vessels are supplied in a plug-and-play mode and may be operated immediately upon installation to the concrete foundation.

Unpressurized cryogenic storage reservoirs

“GazSurf” offers to supply stationary cryogenic unpressurized reservoirs varying in storage volume from 200 up to 5000 m3 for storage and distribution of liquid nitrogen (LN2), liquid oxygen (LO2), liquid argon (LAr) and liquefied natural gas (LNG).

From the construction standpoint a stationary cryogenic reservoir is comprised of two vessels — an inner storage tank inside an outer shell. The inner vessel is manufactured out of austenitic stainless steel, the outer (shell) is manufactured from low alloy carbon steel. Both vessels are attached to a concrete foundation by the anchor bolts.

The space between the outer shell and inner storage tank serves as a thermoinsulating layer and is filled by the insulating material — perlite.

A layer of foamed glass blocks under the bottom of the inner storage tank serves as thermoinsulation from the concrete foundation.

Cryogenic reservoirs are fitted with manholes for access to the inner storage tank, insulating space and for perlite filling.

For access to the manholes, block valves and safety instruments and mechanisms on the top and sides of the reservoir it features fenced walkways and service areas, connected by a fenced ladder on the side of the outer shell of the reservoir.

Cryogenic reservoir comes equipped with process pipelines, block, regulating and safety valves and control and measuring instrumentation devices.

An operating pressure inside the storage tank is kept on a set level by an automated pressure contour that includes pressurization evaporator, pressure instrumentation and control valves with remotely-controlled pneumatic actuators.

To prevent ambient moisture from corrupting the insulating layer periodic purging of it with dry gaseous nitrogen is necessary. A slight overpressure in the thermoinsulating space is achieved by automatic nitrogen supply valve that opens up when the pressure level drops.

Scope of supply:

Reservoir is supplied as a set of components and elements for installation and testing at the site. The following is supplied:

- metal components of the inner storage tank;

- metal components of the outer shell;

- a set of valves (block, regulating, safety);

- pressurization evaporator (for raising the pressure inside the storage tank);

- control and measuring instrumentation (pressure gauges, level gauges);

- process pipelines for filling and purging the reservoir;

- thermoinsulating materials: foamed glass blocks, perlite;

- a set of fenced walkways, service ladders.