"Turn key" in 18 months: complex gas treating plant in Kazakhstan

Customer: ТОО “Ken-Sary” (subsidiary of Korean National Oil Corporation)

Region: Republic of Kazakhstan, Mangistautskaya region, Mangistauskiy district, Arystanovskoye production field (railway station № 66310, Say-Utes)

Plant capacity, feed gas: 150 mln. scm/year

Products:

- NGL (a wide fraction of light hydrocarbons) — up to 50 thousand tons per year

- Dry stripped gas — up to 120 mln. scm/year

Scope of works:

Concept engineering, design, equipment procurement and supply, supervision of installation, startup and commissioning.

Period of completion:

Plant description

150 mln. scm/year feed gas treating plant constructed at the Arystanovskoye production field in Mangistautskaya region of Kazakhstan. The products are: dry stripped gas in compliance with СТ РК

Results

- A marginal 18 months to get the complex turn-key project implemented

- Currently, the customer is operating the plant and keeps producing a high quality commodity

- No major malfunctions or emergencies with the process equipment of the plant has been recorded to date

- Our field engineers execute equipment maintenance operations with due care and in a timely manner, which ensures a smooth and trouble-free run and a steady output of the desired products throughout its operational lifetime

- The plant has proven itself in the demanding conditions of feed gas varying at a rather extended range of regulation parameters

- Strictest safety level is practiced at the plant, compatible with highest international standards

- Return of investment for the customer took less than 2 years

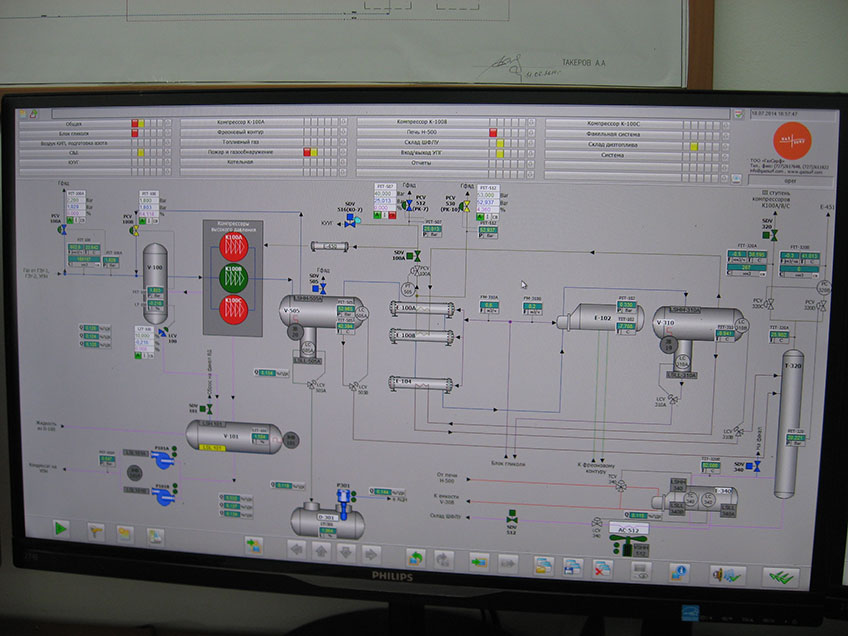

- Control and monitoring system significantly eased the conditions for the operating personnel and minimized the factor of the human error

Control and regulation system

All sections and skids are equipped with advanced sensors and instrumentation, safety, block and control valves. This allows for automatic and distance process control from the control room.

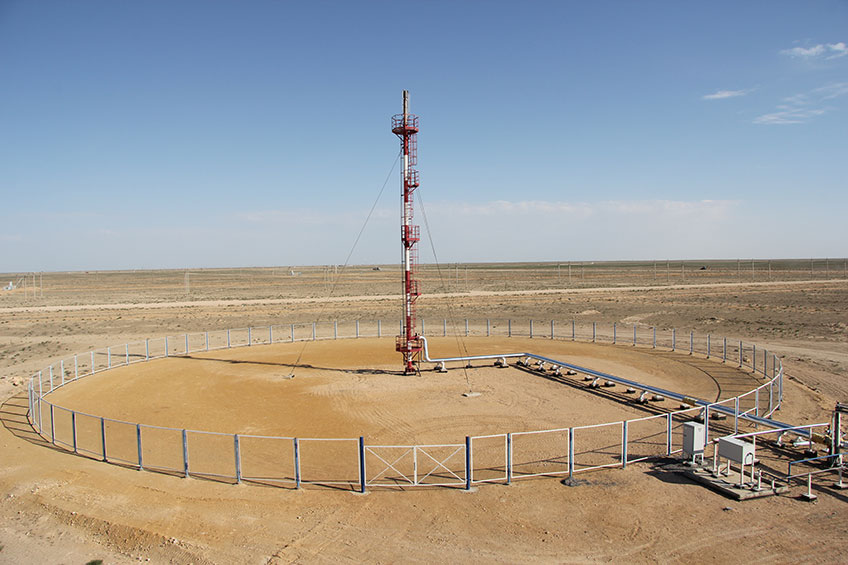

Flaring system

A flaring system is committed to the emergency flaring of the APG. High pressure flare is equipped with two standby burners that are flamed by the fuel gas. Flare construction provides for distance ignition and flame control. Propane reservoirs are a redundant source of fuel for standby burners. Each burner is controlled by the heat sensor and ignition is electronically controlled.

Instrument air and nitrogen section

Instrument dry air required for operation of the process and nitrogen for process purposes are produced at this section.

NGL storage and distribution section

NGLs from the stabilizer-column are stored at the NGL storage to be later distributed by the tank trucks.

The storage is comprised of seven operational and one standby 200 scm each. Distribution of NGL to the truck tanks is practiced by pumps through the loading arms.

Fractionation section

In the heat exchangers of the low-temperature section the APG is cooled down to minus 12°C @ 59 bar(g). A stabilizer-column with no reflux flow to the top plate is then used as a de-ethanizer. Heating of the lower part of the column is conducted by hot media circulation through the reboiler. Process design provides propane and heavier hydrocarbon extraction levels of 64%.

Gas phase of the stabilizer-column product consists primarily of methane, ethane and propane is directed to the suction of the third stage of the feed compressor, part of it is used as fuel gas.

Liquid product from the bottom of the column (NGLs) is cooled at the air-cooler and then flows to the NGL storage.

Glycol injection and regeneration section

An injection of diethylene glycol onto the low-temperature separation section heat-exchangers pipe grids stops the hydrates from forming. Saturated glycol then flows to the stripping oven from where it is returned to the process train. This is a cheap and effective measure of keeping the moisture out of the gas flow and stopping hydrates from forming. Glycol losses from carryover are minimal.

Low temperature separation section

A low-temperature separation process is used for APG treatment with a closed loop chilling cycle based on Freon 134A. the chiller is based on two GEA Freon compressors manufactured in the US. Chiller compressors are housed separately, which helps to keep operation and maintenance easy and comfortable. This solution provides an ease of exploitation which prolongs the operational lifetime of compressors while keeping the performance stable.

Project goals

New state regulations were passed into place in Russian Federation in 2012 and in the Republic of Kazakhstan in 2014. These required that 95% of the associated petroleum gas (APG for short) produced by the oil companies be utilized in one way or another. It limited the amount of gas to be flared and significantly increased the penalties for flaring extra amounts of APG. In Russian Federation the regulation law is called “On the measures to stimulate reduction of ambient air pollution by products of associated petroleum gas flaring”, while in Republic of Kazakhstan these are a part of the law called “On mineral resources and management thereof”. The penalties for over flaring are quite harsh.

These regulations set the ultimate goal to the project: to provide an effective APG-treating solution with minimal resources and within the shortest possible timeframe with products that ensure both compatibility with new laws of the Republic of Kazakhstan and shortest possible return on investment.

These two aims were successfully reached by our company. We managed to get this project from scratch to turn-key commissioning in an astonishingly short period of 18 months.

Process solutions

Unlike the typical natural gas, the production of which may be regulated to keep in line with demand and usage, APG is a by-product of crude oil recovery and its output does not correlate to the presence or absence of utilization means. This lead to the creation of a feed-end system that could regulate an amount of feed gas in a wide range of APG flows and conditions. The Process solutions employed at this section by our engineers are based on the extensive experience of North-American oil&gas producers and allow to regulate the amount of feed APG in a safest and most effective way.

To provide the solutions for the aims described above a complex gas treating plant has been designed and constructed along with the NGL storage and distribution system. The plant may be broken into a number of sections specified below and with a specific process role.

Scope of equipment

- Compressor station based upon Ariel JGK/4 reciprocating compressors driven by Waukesha L7044 gas engines (2 operational, 1 stand by) with a capacity of 15000 scm/hour @ 6 МPа

- Low temperature separation section with a hydrocarbon dew point of minus 11 0С

- Glycol regeneration unit with a circulation of 0,9 scm/hour

- Fractionation section with a production of up to 50 000 tons of NGL per year and up to 120 mln. scm/year of dry stripped gas

- Instrument air and nitrogen section with a capacity of 30 scm/hour of nitrogen, and 200 scm/hour of dry air

- 1200 kW low temperature separation section based on two GEA 400GLE compressors 261 kW each

- 1600 scm NGL storage and distribution section

- Flaring system with a 21000 scm/hour flow

- Complete control and regulation system

Compressor station

ompressor station, based upon three advanced reciprocating Ariel compressors, is tasked with compressing the feed APG to 60 bar(g). The compressors are housed in a spacious modular building allowing for an easy and trouble-free maintenance and overhaul of the equipment. This solution provides an ease of exploitation which prolongs the operational lifetime of compressors while keeping the performance stable.